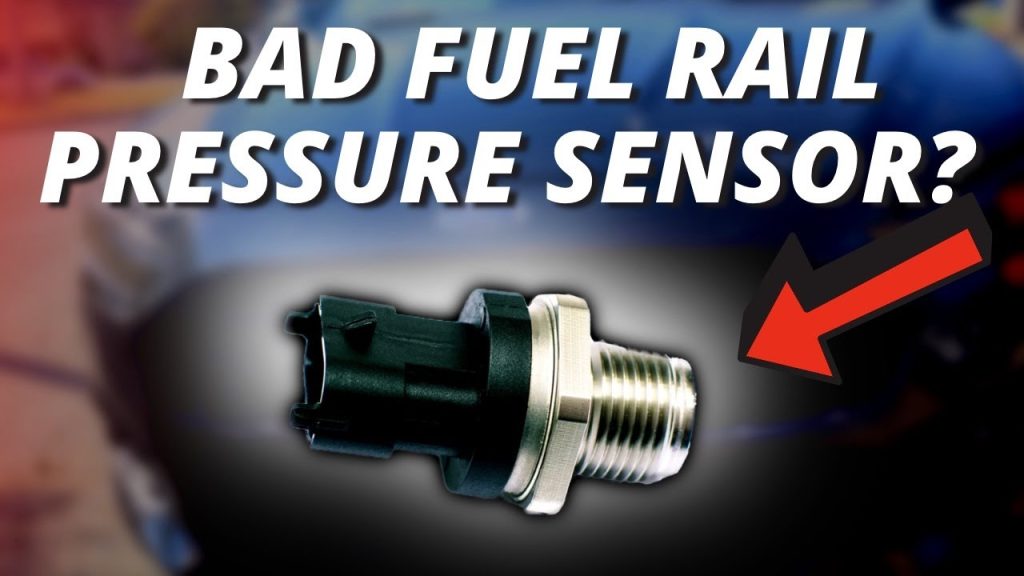

The fuel rail pressure sensor is a critical component in modern diesel and gasoline engines. It plays a vital role in ensuring optimal engine performance, fuel efficiency, and emissions control. If you’ve been researching engine issues or simply want to learn more about how your vehicle works, this guide will provide you with everything you need to know about the fuel rail pressure sensor, its function, common symptoms of failure, and how to address potential problems.

What Is a Fuel Rail Pressure Sensor?

The fuel rail pressure sensor, also known as the FRP sensor, monitors the pressure of fuel within the fuel rail (the pipe that delivers fuel to the injectors). This data is sent to the engine control unit (ECU), which uses it to adjust fuel delivery for optimal combustion.

In diesel engines, maintaining precise fuel pressure is especially important because high-pressure systems are used to atomize fuel for efficient burning. In gasoline engines, the sensor ensures the correct air-fuel mixture for smooth operation.

Without an accurate reading from the fuel rail pressure sensor, the ECU cannot make the necessary adjustments, leading to poor engine performance and increased emissions.

How Does the Fuel Rail Pressure Sensor Work?

The fuel rail pressure sensor operates by measuring the pressure of the fuel in the rail and converting it into an electrical signal. This signal is then transmitted to the ECU, which adjusts injector timing, fuel pump output, and other parameters to maintain the ideal fuel pressure.

Key points about its operation:

- The sensor is typically located on or near the fuel rail.

- It provides real-time data to ensure consistent fuel delivery under varying driving conditions.

- Modern sensors are highly sensitive and capable of detecting even small changes in pressure.

Common Symptoms of a Failing Fuel Rail Pressure Sensor

When the fuel rail pressure sensor fails or begins to malfunction, it can cause a variety of issues. Here are some of the most common symptoms to watch for:

1. Check Engine Light Illuminated

One of the first signs of a problem is the illumination of the Check Engine Light on your dashboard. The ECU may detect irregularities in the fuel pressure readings and trigger the warning light.

2. Poor Engine Performance

A faulty sensor can lead to incorrect fuel delivery, causing rough idling, hesitation, or sluggish acceleration. You may notice a significant drop in engine power, especially under load.

3. Hard Starting or No Start Condition

If the sensor sends inaccurate data to the ECU, the engine may struggle to start or fail to start altogether. This is because the ECU cannot determine the correct amount of fuel needed for ignition.

4. Reduced Fuel Efficiency

Erratic fuel pressure readings can cause the engine to consume more fuel than necessary, leading to decreased mileage and higher operating costs.

5. Excessive Smoke from Exhaust

In diesel engines, a failing fuel rail pressure sensor can result in improper combustion, producing thick black smoke from the exhaust. This is often accompanied by a strong fuel odor.

6. Stalling or Misfires

If the sensor fails completely, the engine may experience misfires or stall unexpectedly while driving. This can be dangerous, especially in traffic or on highways.

Causes of Fuel Rail Pressure Sensor Failure

Several factors can contribute to the failure of a fuel rail pressure sensor:

- Electrical Issues: Corroded or damaged wiring can disrupt the sensor’s ability to communicate with the ECU.

- Contamination: Dirt, debris, or moisture entering the sensor can impair its accuracy.

- Wear and Tear: Like all components, the sensor has a limited lifespan and can degrade over time.

- High Temperatures: Prolonged exposure to heat can damage the sensor’s internal components.

- Fuel System Problems: Issues like clogged fuel filters or failing fuel pumps can place additional stress on the sensor.

How to Diagnose a Faulty Fuel Rail Pressure Sensor

If you suspect your fuel rail pressure sensor is failing, here are some steps to diagnose the issue:

- Scan for Error Codes: Use an OBD-II scanner like this reliable diagnostic tool to retrieve trouble codes related to the fuel system. Common codes include P0190, P0191, P0192, and P0193.

- Inspect Wiring and Connections: Check for loose, corroded, or damaged wires and connectors around the sensor.

- Test the Sensor: Use a multimeter to measure the sensor’s voltage and resistance. Compare the readings to the manufacturer’s specifications.

- Monitor Live Data: Advanced OBD-II scanners can display live fuel pressure data, allowing you to see if the sensor is providing accurate readings.

Solutions for a Faulty Fuel Rail Pressure Sensor

Once you’ve confirmed that the sensor is faulty, here are some steps you can take to resolve the issue:

1. Clean the Sensor

Sometimes, dirt or debris can interfere with the sensor’s operation. Use an electronic cleaner like this contact cleaner to gently clean the sensor and its connections.

2. Replace the Sensor

If cleaning doesn’t solve the problem, replacing the sensor is often the best solution. Look for a high-quality replacement like this durable fuel rail pressure sensor to ensure long-lasting performance.

3. Address Underlying Issues

Before installing a new sensor, inspect the fuel system for other problems, such as clogged filters or failing pumps. Fixing these issues can prevent premature failure of the new sensor.

4. Perform Regular Maintenance

Regularly check and replace fuel filters, use high-quality fuel, and keep the engine bay clean to reduce the risk of sensor failure.

Preventing Fuel Rail Pressure Sensor Problems

Prevention is always better than cure. Here are some tips to extend the life of your fuel rail pressure sensor:

- Use High-Quality Fuel: Clean fuel reduces the risk of contaminants affecting the sensor (Source: Diesel Technology Forum ).

- Keep Electrical Connections Clean: Regularly inspect and clean wiring and connectors to prevent corrosion.

- Follow Maintenance Schedules: Stick to your vehicle’s recommended maintenance schedule to catch potential issues early.

Conclusion

The fuel rail pressure sensor is a small but essential part of your vehicle’s fuel system. By understanding its function, recognizing the symptoms of failure, and knowing how to address problems, you can keep your engine running smoothly and avoid costly repairs. Whether you’re diagnosing an issue or simply performing routine maintenance, paying attention to this critical component can save you time and money in the long run.

Have questions about your fuel rail pressure sensor or need advice on replacements? Leave a comment below—we’re here to help!

Disclaimer: Always consult a professional mechanic if you’re unsure about diagnosing or repairing complex components like the fuel rail pressure sensor.