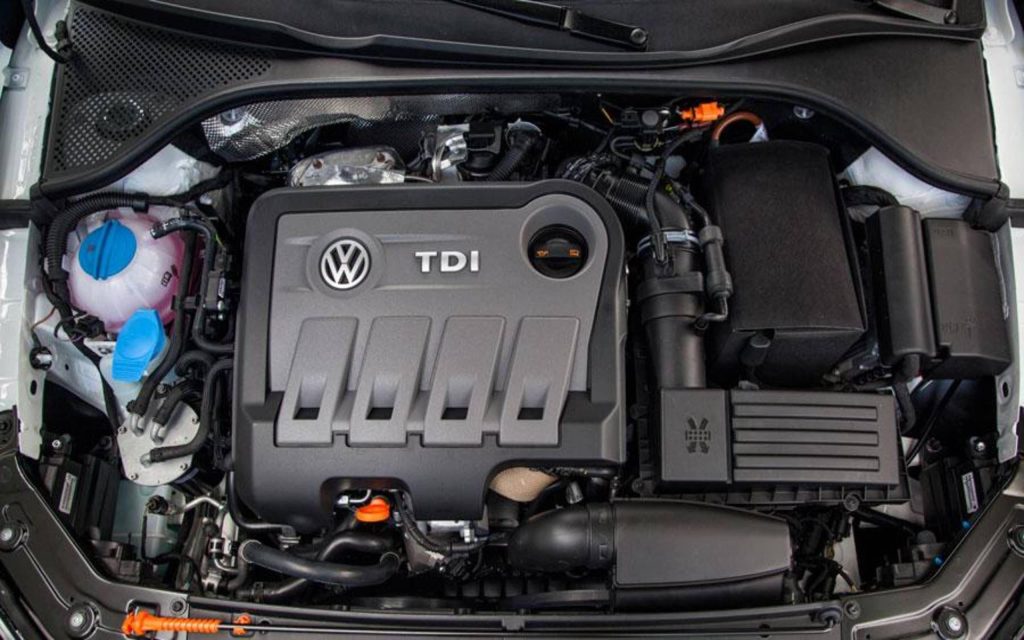

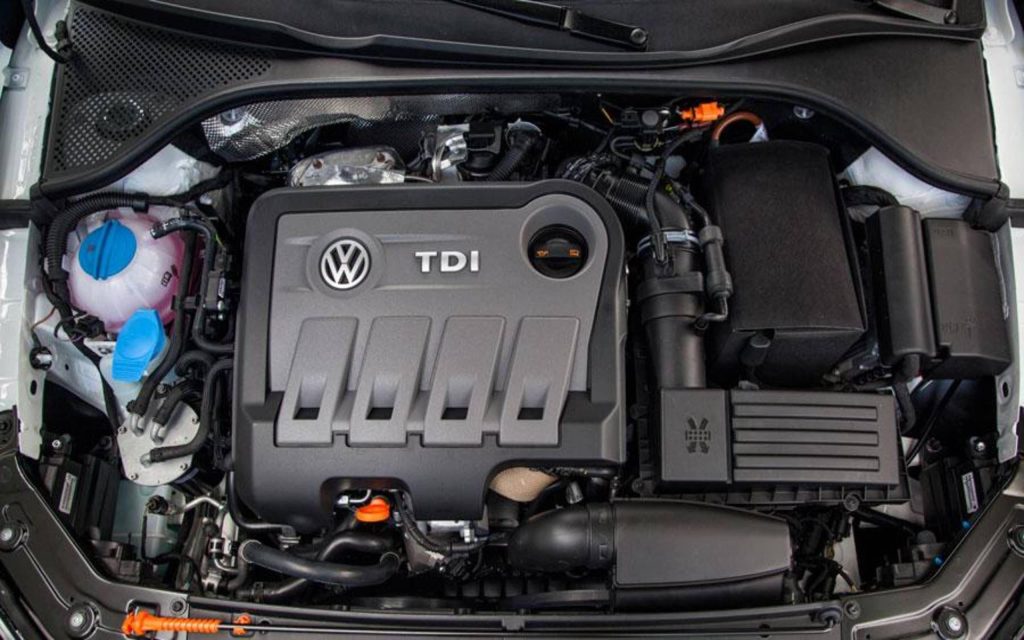

The Volkswagen 2.0 TDI is one of the most widely used diesel engines in Europe. You will find it in everything from the Golf and Passat to the Audi A3 and Skoda Octavia. It has a reputation for solid power and strong fuel economy but if you have owned one long enough you know the turbo is often the first thing to cause problems.

When the turbo starts failing you are left with either sluggish acceleration or a complete loss of power. It is expensive to replace but the good news is that most failures can be prevented if you catch the warning signs early.

Let’s go through the most common turbo issues on the 2.0 TDI and what you can do to stop them before they get worse.

Turbo Overboost and Limp Mode

There is nothing worse than stepping on the accelerator and getting nothing. One second your turbo is working fine and the next your car is in limp mode refusing to give you power.

Common signs include sudden loss of acceleration power, a check engine light with the P0234 overboost condition code, black smoke from the exhaust or a high-pitched whistling sound from the turbo.

The usual cause is carbon buildup on the turbo’s internal vanes. When enough soot collects inside the turbo it prevents the vanes from adjusting airflow properly. This leads to too much boost at low RPMs or not enough boost when you need it most. The ECU detects the problem and shuts the turbo down to protect the engine.

Fixing this requires running a turbo cleaner through the system to dissolve the carbon. In some cases the turbo needs to be removed and cleaned manually. If the actuator is also failing the vanes may not be adjusting properly so testing it should be part of the diagnosis. If the turbo vanes are completely stuck a rebuild or replacement is the only option.

Ignoring overboost issues is a quick way to destroy your turbo entirely.

Turbo Actuator Failure and Boost Problems

The turbo actuator is a small but critical part of the system. It controls the vanes inside the turbo to regulate boost pressure. If it fails your turbo will either overboost or fail to spool properly leading to sluggish performance.

Common signs of actuator failure include turbo lag or delayed boost response, erratic acceleration, a check engine light with code P2563 for the turbo boost control position sensor circuit or a clicking noise coming from the actuator itself.

In older 2.0 TDIs the actuator is vacuum controlled but on newer models it is electronic. Both can fail due to wiring issues, internal gear wear or electrical faults.

To fix it check for vacuum leaks or damaged wiring first. If those look fine the actuator itself is likely faulty and needs to be replaced. This is a much cheaper fix than replacing the entire turbo.

Many turbo issues are misdiagnosed as a complete failure when the real issue is just the actuator.

Oil Starvation and Turbo Bearing Failure

The fastest way to destroy a turbo is to starve it of oil. The 2.0 TDI has a known issue with clogged oil feed lines which can cause premature bearing wear and eventual turbo failure.

Common signs include a high-pitched whining or siren-like noise from the turbo, excessive blue smoke from the exhaust, a burning oil smell and rough engine performance. If the turbo is inspected there may be excessive shaft play indicating worn bearings.

The most common causes are sludge buildup in the oil feed line, poor-quality oil or extended oil change intervals that allow carbon deposits to form.

Fixing this problem requires replacing the oil feed and return lines when installing a new turbo. Flushing the oil system will also prevent sludge buildup from coming back. Always use a fully synthetic VW-approved oil like 5W-30 or 0W-30 to minimize carbon deposits.

Once a turbo starts making grinding noises it is only a matter of time before it fails completely.

Whistling or Grinding Turbo Noises

If your turbo suddenly starts sounding like an ambulance siren that is a sign that something is very wrong. A failing turbo will often make a high-pitched whine or even a grinding noise as the bearings wear out.

Common signs include excessive turbo lag, a drop in power under acceleration, increased exhaust smoke and oil leaks from the turbo seals.

This happens when the turbo bearings wear out due to high mileage, lack of oil lubrication or overheating. Once they start making noise the turbo is already in bad shape.

Fixing this issue means checking for excessive shaft play in the turbo. If the turbo shaft has movement the bearings are shot and the turbo needs to be replaced.

Should You Be Worried About Your 2.0 TDI Turbo

If properly maintained the Volkswagen 2.0 TDI turbo can last well over 250000 kilometres. The problem is that most people do not stay on top of maintenance and common turbo failures happen far earlier than they should.

To keep your turbo healthy change the oil every 10000 to 12000 kilometres using VW-approved synthetic oil. Replace the turbo oil feed line every 100000 kilometres to prevent clogging. Run a turbo cleaner through the system to prevent soot buildup and check the actuator and vacuum system if boost pressure is inconsistent.

A little maintenance now will save you a major repair bill later.

Final Thoughts and Where to Get Replacement Parts

If your turbo is showing signs of failure do not replace it without addressing the root cause. Many 2.0 TDI owners replace their turbo only for the new one to fail again because they ignored carbon buildup, oil starvation or actuator issues.

Do not wait until your turbo fails completely Fix the issue before it becomes an expensive repair.