Diesel fuel contamination is a major concern for vehicle owners and fleet operators. One of the key components that help prevent engine damage due to water contamination is the diesel water separator. This device ensures that excess water is removed from the fuel before it reaches the engine, helping to maintain efficiency and prolong engine life. In this guide, we’ll discuss the importance of diesel water separators, how they work, and how to maintain them properly.

Why Are Diesel Water Separators Important?

Water contamination in diesel fuel can cause significant engine issues, including:

- Corrosion of fuel system components

- Reduced fuel efficiency

- Bacterial growth in the fuel tank

- Injector and fuel pump damage

Diesel water separators work by filtering out water and other contaminants from the fuel before it enters the engine. This ensures cleaner fuel combustion and prevents costly repairs.

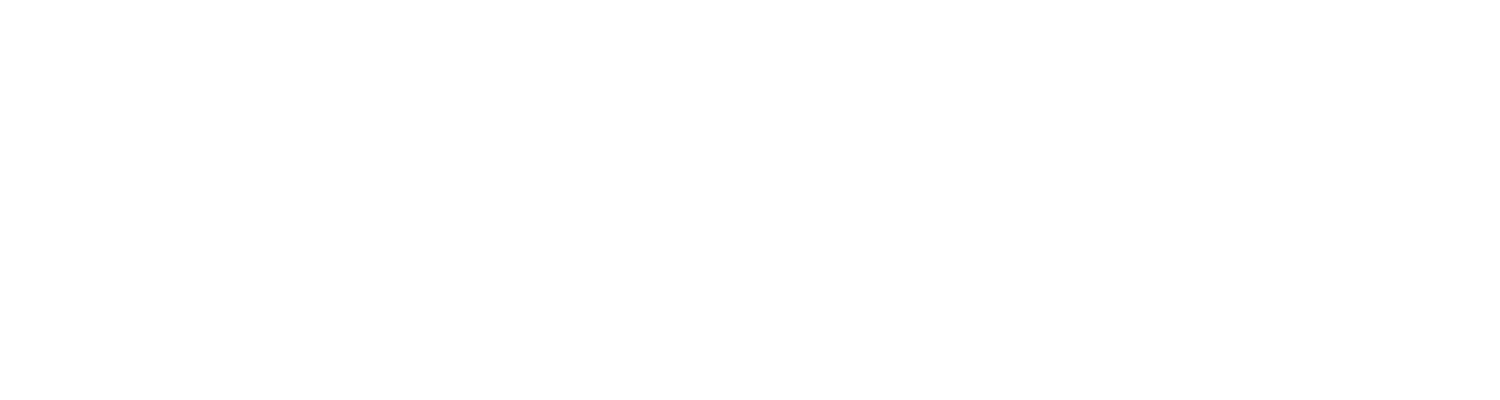

How Does a Diesel Water Separator Work?

A diesel water separator typically consists of:

- A primary filter that removes large debris and contaminants.

- A separation chamber where water and fuel are separated by density.

- A drain system that allows users to remove collected water manually or automatically.

Modern water separators use centrifugal force or coalescing filtration technology to separate water efficiently. For an in-depth explanation, check out this resource from FleetOwner on Diesel Water Separators.

Signs Your Diesel Water Separator Needs Maintenance

If your diesel water separator is not functioning properly, you may notice:

- Water in the fuel filter

- Loss of engine power

- Rough idling or engine misfires

- Frequent fuel system clogging

How to Maintain a Diesel Water Separator

Regular maintenance of your diesel water separator is crucial to keeping your fuel system in top condition. Here’s how you can maintain it:

Step 1: Regular Inspection

- Check the separator for signs of water accumulation at least once a month.

- Inspect fuel lines and connectors for leaks.

Step 2: Draining the Water

- Locate the drain valve at the bottom of the separator.

- Place a container underneath and open the valve to let out water.

- Close the valve once only diesel fuel starts to come out.

Step 3: Replacing the Filter

- Follow your vehicle manufacturer’s guidelines on filter replacement intervals.

- If your separator has a disposable filter, replace it as needed.

For detailed maintenance steps, refer to this Cummins guide on diesel fuel filtration.

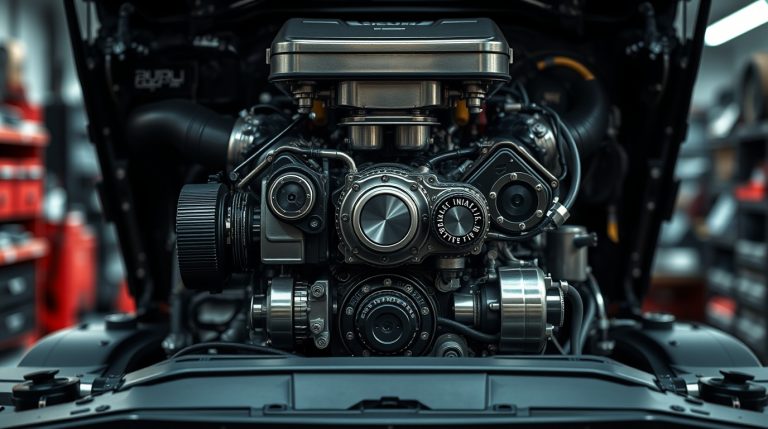

Choosing the Right Diesel Water Separator

When selecting a diesel water separator, consider:

- Flow rate compatibility with your engine

- Filtration efficiency (measured in microns)

- Drain system type (manual vs. automatic)

- Brand reputation and OEM recommendations

Conclusion

A diesel water separator is a critical component for keeping your engine running efficiently by preventing water contamination in your fuel system. Routine maintenance, including draining water and replacing filters, ensures optimal performance and extends engine life. For more insights, read this study on fuel contamination from the U.S. Department of Energy.

By taking proactive care of your diesel water separator, you can prevent costly engine damage and improve fuel efficiency, keeping your vehicle in peak condition.